Learning to weld

In order to create her durational performance, ‘FORGE’, Rachel Mars first had to learn to weld. In the process she learned the difference between welding badly and welding well, how to aim for slugs, not worms, and to listen to the sound of the weld.

In these images and voice notes, Rachel introduces us to some artefacts of her learning and rehearsing the skill of welding, and reflects on some of the language involved.

Read the full transcript below:

So, many years ago now, I think it was like 20- oof, 2017 or 2018, I did a first welding course and that was at London Sculpture Workshop. And that was called ‘Welding for Artists’ and that was really just about introducing the basic techniques of like, what welding even is. And we welded with a MIG welder, and we welded with a TIG welder, which are two different ways of welding – it’s basically two different ways of introducing a material that gets really hot that joins two pieces of metal together.

And the picture is of a coffee table, which is the thing that I made in my second welding course, at Blackhorse Road Studios, also in London. So that was a weekend course and the aim of that was to get you to bring something home, that you’d finished. And so I made this coffee table. Which is pretty basic – it’s basically lots of joining together of steel pieces and then whacking a wooden top on the top of it. And there’s a – I’ve sent you a close-up picture of one of the welds, which – well this now lives in my garden, so it’s, you can see that it’s got really, really rusted.

So the sort of extra-rusty bit is the weld – so that’s the bit where you’re joining two pieces of metal together. And it’s – you can do quite a bad weld, as long as they actually, the pieces are joined together. And then you sort of grind it down, so it’s flat. But you can see that I haven’t ground down the bit on the inside of that picture, on the inside of the joint. So you can see, it’s kind of bulbous. Which, I mean, it’s still functional, but it’s just got a – it’s a little bit fat. Bit of a fat weld.

And that was using a MIG welder, so that’ s when you are using a welder that – a welding machine that’s already got wire kind of pre-loaded into it. And it comes out like a gun, and it’s joined up to electricity and also gas. And what you’re doing is that wire is getting super super hot and melting the spaces in between – that’s sort of what’s shooting out and melting the spaces in between the two bits of metal that you’re trying to join together.

So, this is like a functional table. It is quite ugly and basic, but it does the job. My cat sits on it a lot. And I would say that took, with the teaching, that took probably a day to do. I’m quite slow at welding.

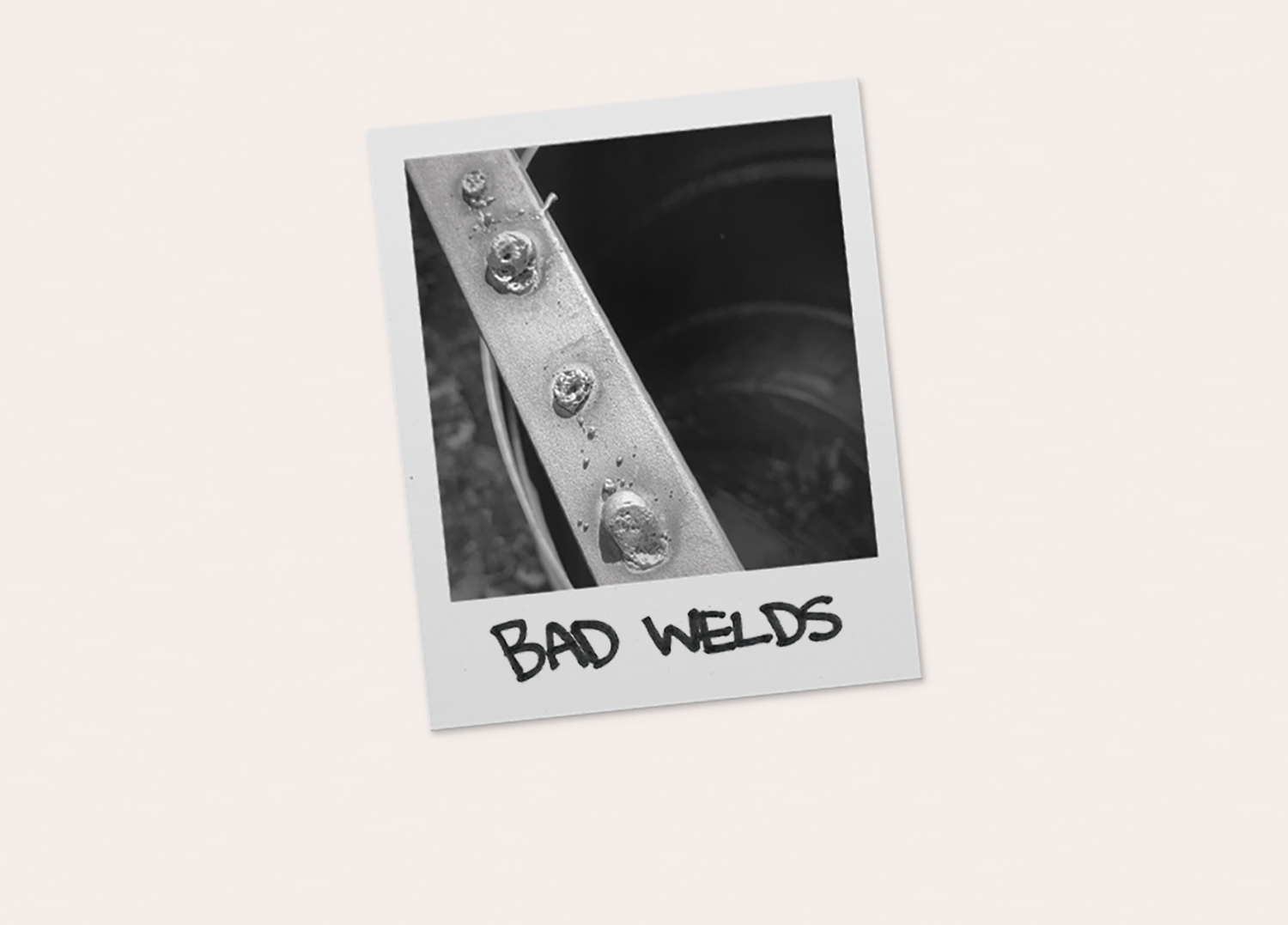

OK, so this is a picture of some bad welds! [laughs] So this is from the, an offcut from the steel that I’m using to make the Dachau replica gate. So it’s, the material is called ‘mild’ steel and this is again this is me with a MIG welder – ‘Metal Inert Gas’. So you’ve got this welding gun and it feeds a wire electrode that is also the sort of filler material to join two metal pieces. That’s sort of what’s going on there. So – what is – why is this – first of all, this is just a practice weld, cause you can see I’m not trying to join two pieces of metal together, I’m just sort of – It’s a bit like, I don’t know, a rehearsal. I was just like, ‘Let me just try and remember how to weld, I’ll do it on this offcut.’

And what you can see is that they are short, they are splattery, there’s kind of, if you look closer there’s like bits of tiny material that have kind of shot off in little bulbs. You can also see the wire itself has like chopped off and is trapped in a little bit – in the sort of top third there’s a bit of wire that’s caught. So, a good weld shouldn’t have holes in it, and you can see that this is really spattery and it’s got holes in it, if you zoom in. So that is not good because that is not gonna be strong.

And it’s got craters in it, it’s got – it’s just a hot mess, basically.

And the reason it looks like this, I found out afterwards, is because the gas wasn’t being fed through properly, so there was basically no gas. And it wasn’t – the gas kind of protects it, makes it smooth, and it just there was no gas so it was splattering. So there’s this sort of thing where – how do you know what a good weld is? Well it should be sort of straight, uniform, no holes, and sort of quite smooth, like a kind of flat slug. And the other thing is, you can tell if you’ve done a good weld by, there’s this kind of phrase – ‘A good weld sounds like bacon frying.’ So if you’re listening to someone welding and it’s got this kind of even sound of someone – of like bacon frying, that’s a good weld. If it’s like [squelchy noises] and it’s erratic, then that’s probably the sound of a bad weld.

So hopefully I will be back to my good welding, because I will have understood how to turn the gas on properly. But that is, yeah that is an example of when welding goes bad.

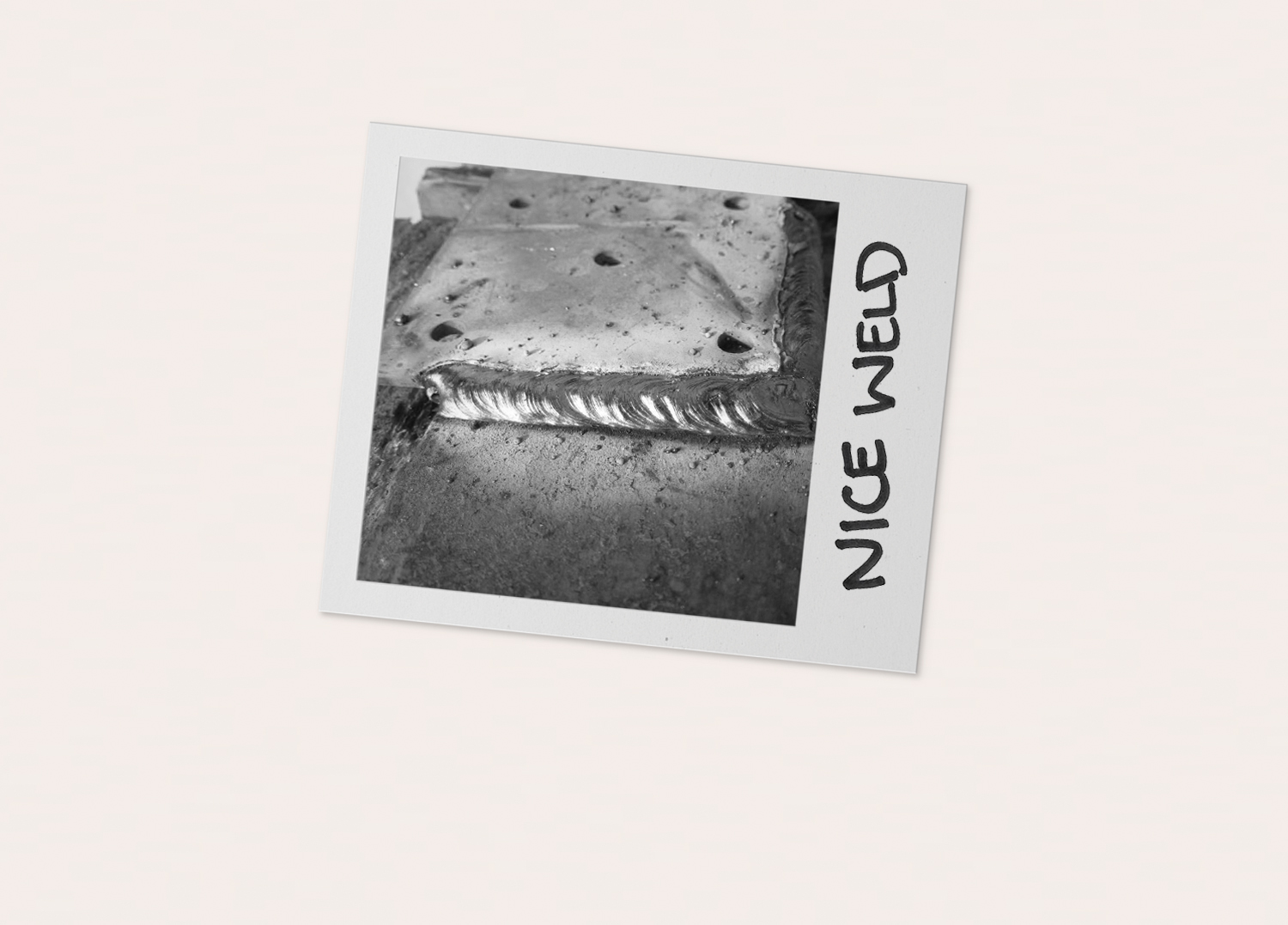

Ok, this is a really nice weld. So, how do we know? So it’s got – it’s quite flat. I know you’re looking at a flat image, so you can’t turn it. But it’s not huge, like a sort of big worm. It’s flatter to the material. And you can see – you can probably see – you can see in it, the way that basically when you’re moving the gun very slightly left to right, and right to left, right to left, left to right, left to right, right to left. Like you’re doing this kind of mini mini dance. So you’re not just moving in one straight line, you’re going side to side and you can see the result of that on this weld because it’s got these kind of little arcs. That is a good sign.

It’s also, it’s not too wide. The whole thing – it’s called a ‘bead’ – the bead is not too wide. And because the other – the things you’re trying to control, so I talked a bit about the gas being a problem in the last weld. The other things you can get wrong – well, there’s quite a lot – but you can move too quickly, and so it gets like, narrow, and it doesn’t properly penetrate the metal. And then you’re not gonna get two things that are stuck together well. If you go too slowly, then you’re putting too much heat into the weld, and you can basically burn through the thing that you’re trying to fit together. So then you’d have like, the bead would be too wide, and it would be too hot. So, that is a way – more ways to do it badly, basically.

There’s some language around welding that I quite like. The main thing I quite like is about the speed of travel. And there’s this phrase, ‘don’t dwell on it’. So, if you ‘dwell’ on a weld, that is when you’re taking too much time, you’re not moving fast enough. And you get this kind of – it’s definitely not flat if you dwelt on it – it’s like, ugly and fat, both in its width and it’s too high. So yeah, ‘don’t dwell on it’ I think is a great – and we say that all the time, as a phrase. But I’m kind of – dwelling on a weld is like an actual thing.

And I – I don’t know, especially with a project that is thinking about memory, and grief, and how to live in the present with a past – historical past that’s full of trauma and grief, but how to kind of be active and responsible, and, yeah being more of an activist in the present. And I think this notion of, you know, ‘don’t dwell on it’ becomes really important. So that’s another reason why I like that language.

[Ends]